Demand Background

As the national demonstration base for the new industrialization of marine engineering equipment, Nantong City boasts large scale of shipbuilding industry, which can achieve high-quality development only through digital shipbuilding. Although simulation technology is a core technology for the digital transformation of shipbuilding and marine equipment manufacturing enterprises, its application penetration rate is relatively low.

Solution

Based on the resources of the Beijing Center of National Innovation Institute of Digital Design and Manufacturing, IBE has led the establishment of the Ship Marine Equipment Digital Simulation Center in Nantong under the support of the Nantong Chongchuan Economic Development Zone. Meanwhile, a marine equipment digital simulation platform has been constructed together with the China Shipbuilding Industry Association and leading enterprises in the shipbuilding industry.

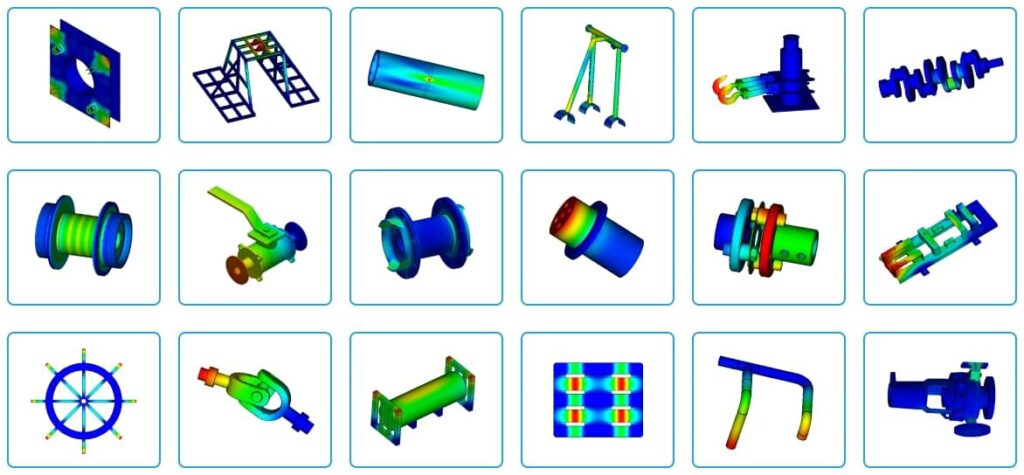

Based on the architecture of “PaaS +App” and the general multiphysics simulation PaaS platform, Simdroid, developed by IBE, this platform has developed hundreds of simulation apps according to typical application scenarios and actual engineering needs of marine engineering, which covers scenarios such as propeller, anchor system, deck, pipeline system design, and hull segmented lifting engineering. It can be applied to component design evaluation, iterative optimization, virtual verification safety assessment, and optimization of work processes.

1. PaaS

The platform supports cloud-native deployment and has a unified and universal data interface and secondary development interface, which can achieve cloud deployment and online application of simulation apps. The platform can be deployed in both public and private clouds.

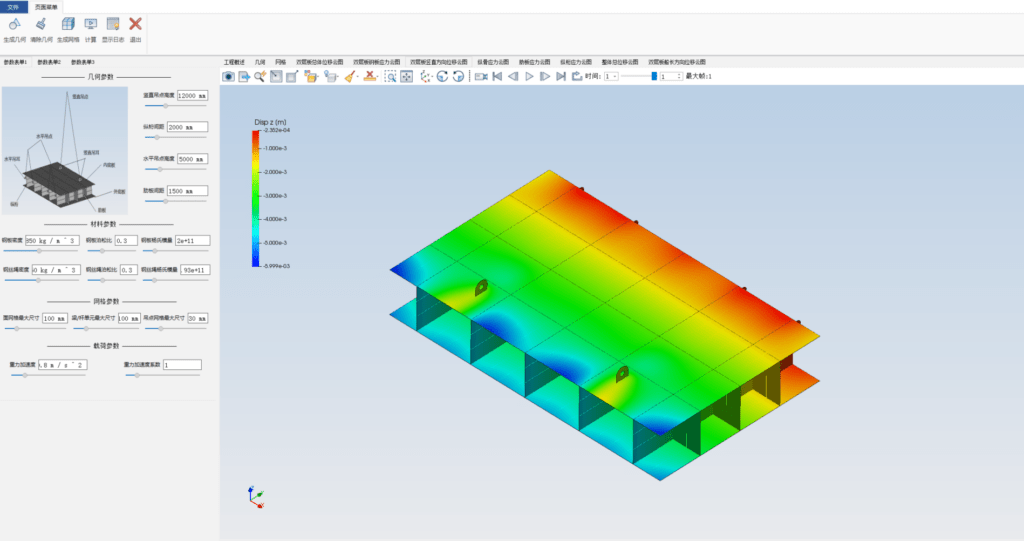

2. Simulation App

The simulation app integrates industry standards, professional knowledge, and engineering experience. Take the simulation app for hull-segmented lifting engineering as an example. During the lifting process, the hull segments are inevitably subjected to deformation and stress concentration due to the structure’s weight and the pulling force of the lifting ropes. Especially when flipping over, there are structural safety hazards, and in severe cases, permanent plastic deformation or even fracture may occur. Therefore, it is necessary to conduct structural strength verification for segmented lifting to ensure the safety of the lifting process and provide a basis for subsequent structural reinforcement plans. The simulation app for hull segmented lifting engineering can help engineers conduct finite element calculations on the lifting model before segmented lifting, evaluate lifting safety, segmented lifting deformation, etc., making lifting engineering more convenient and safer.

Future Applications

The digital simulation platform for marine engineering equipment has been promoted to more than ten industry clients at present, significantly lowering the threshold for small and medium-sized enterprises to apply simulation technology, promoting the application of simulation technology in the field of marine engineering equipment, and assisting in the digital transformation of manufacturing enterprises.